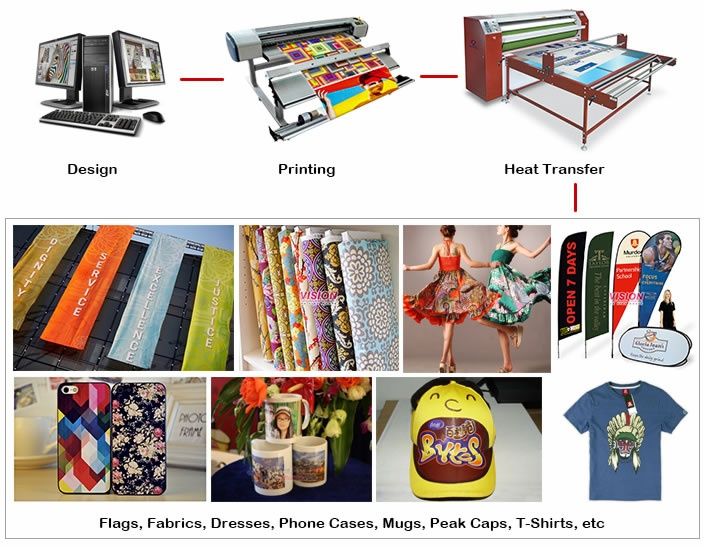

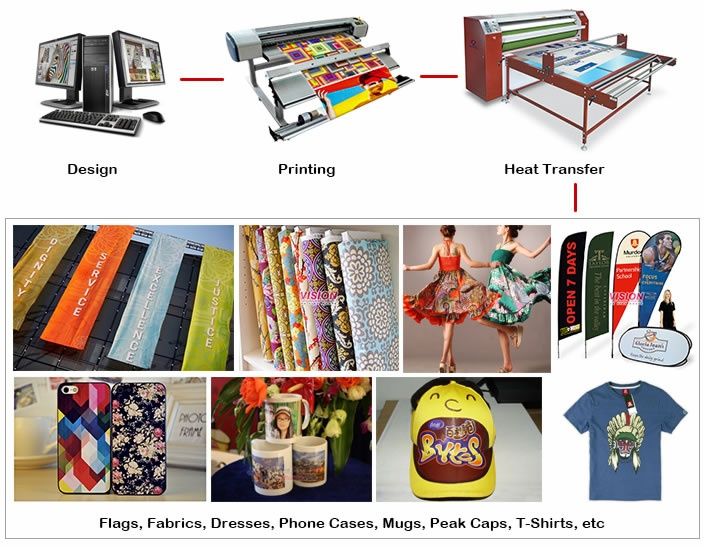

1. Sublimation method

This is the most commonly used method. Using the sublimation characteristics of disperse dyes, disperse dyes with molecular weight of 250 ~ 400 and particle diameter of 0.2 ~ 2 microns, water-soluble carriers (such as sodium alginate) or alcohol-soluble carriers (such as ethyl cellulose) and oil-soluble resins are used to make

Sublimation Ink, which is treated on a

Heat Transfer Machine at 200 ~ 230 ° C for 20 ~ 30 seconds, transfer disperse dyes to synthetic fibers such as polyester and fix them.

2. Swimming method

The dye in the ink layer of the

Heat Transfer Paper is selected according to the properties of the fiber. The fabric is first soaked and rolled with a mixture of color fixing additives and pastes, and then the dye is transferred from the transfer printing paper to the fabric and fixed by hot press swimming in the wet state. Finally, it is subjected to wet treatment such as steaming and washing. During dye transfer, there needs to be a large pressure between the fabric and the

Sublimation Paper.

3. Melting method

The ink layer of transfer paper takes dye and wax as the basic components. Through melting and pressurization, the ink layer is embedded in the fabric to transfer part of the ink to the fiber, and then the corresponding post-treatment is carried out according to the properties of the dye. When the melting method is used, a large pressure is required, and the dye transfer rate increases with the increase of pressure.

4. Ink layer stripping method

Using the heat transfer ink that can produce strong adhesion to the fiber after heat, the whole ink layer can be transferred from the transfer paper to the fabric under a small pressure, and then the corresponding color fixing treatment can be carried out according to the properties of the dye.